Centre for Engineering Research (CER)

The Centre for Engineering Research (CER) delivers excellent research and high-quality innovation where original ideas, fundamental and applied knowledge push and continue to develop the frontiers of engineering science in both outputs and impact.

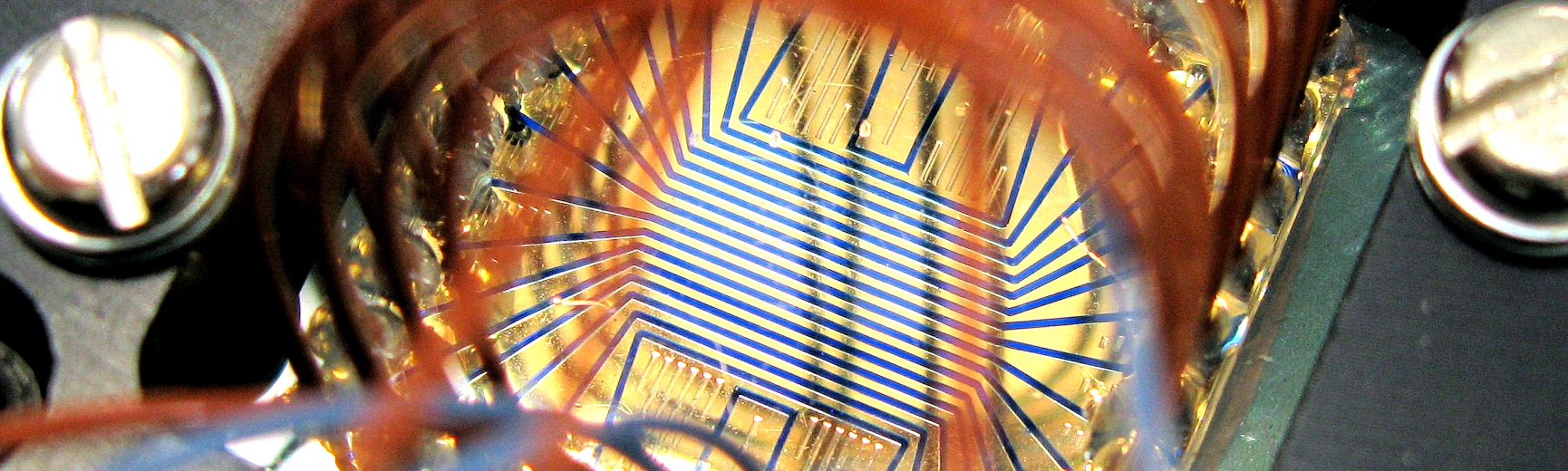

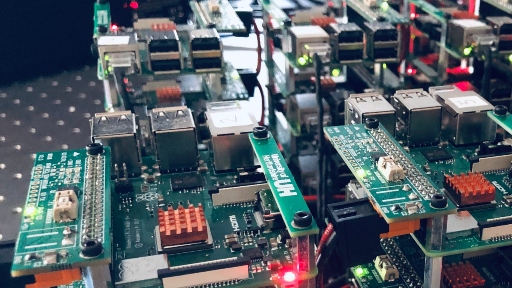

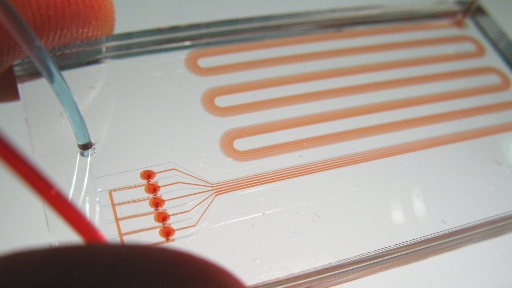

Research at CER cuts across multiple disciplines drawing together more than 40 academic and research staff and over 70 PhD and EngD students from electrical and electronic, material and manufacturing, civil, aeronautics and mechanical engineering and their associated disciplines. These include power, embedded systems, communications, information engineering, materials, aerospace and civil structures, energy, microfluidics, microengineering and bioengineering.

The Centre comprises of research groups mapping into five university-wide research themes and the UKRI and industrial strategy grant challenges.

Professor Pandelis Kourtessis

Centre Director

Pandelis Kourtessis is a Professor of Cognitive Networks and Associate Dean Research for the Department of Engineering and Technology with Associate Dean Research and Enterprise for the School of Physics, Engineering and Computer Science (SPECS)

He is also Associate Dean Research for the School of Engineering and Technology.

Professor Kourtessis has a track record in passive optical networks, software defined networks, 5G RANs, and the consolidation of 5G and satellite networks. Pandelis has received funding from FP7, H2020, ESA, IUK and for projects collaborating with UK industry.

Leaders of Research Groups in CER

- Andreas Chrysanthou - Professor of Materials Engineering, leader of the Material and Structures (MAST ) Research Group

- Yong Kang Chen - Professor of Applied Mechanics, leader of the Energy and Sustainable Design (ENESD) Research Group

- Yichuang Sun - Professor of Wireless Communications, leader of the Communications and Intelligent Systems (CIS ) Research Group

- Ian Johnston - Associate Professor and leader of the Microfluidics and Microengineering Research Group (MMRG)

Get in touch

For enquiries and the opportunity to engage with the Centre for Engineering Research, please contact Professor Pandelis Kourtessis at p.kourtessis@herts.ac.uk, or +44 (0) 1707 284179.